MAINTENANCE | Essential Steps for Melt Pressure Transducer Calibration

- Bob

- Sep 5, 2025

- 2 min read

Quick Guide: Melt Pressure Transducer Calibration

Audience: Maintenance Leadership

Goal: Get the extruder back up fast with accurate pressure readings

Time Required: ~5 minutes (if no issues)

BEFORE YOU START – Quick Checks

Is the transducer installed and wired properly?

Mounting torque correct (usually 100–200 in-lbs)?

Connector tight?

Wiring verified? (No shorts/opens)

Is the extruder barrel at operating temperature?

Cold barrel = bad readings

Never calibrate a cold transducer

CALIBRATION PROCESS

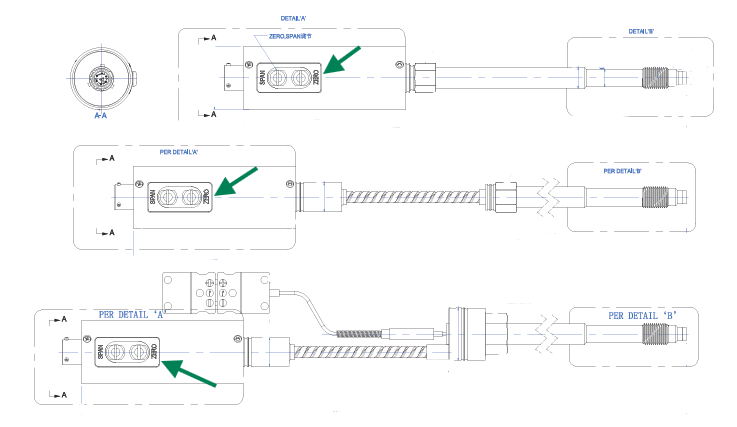

STEP 1: ZERO CALIBRATION (No Pressure in the System)

You MUST do this before material flow starts.

Power up system – wait 2–3 minutes for sensor to stabilize.

Ensure there is no pressure in the barrel (vent open, no backpressure).

Zero the transducer:

On the amplifier, PLC, or HMI: hit “ZERO” or “TARE”.

If using a digital readout, it should now display 0 psi / 0 bar.

✅ If zero won’t hold, check wiring or sensor damage.

STEP 2: SPAN (OPTIONAL – ONLY IF REQUIRED)

Usually factory-set. Skip unless you’ve replaced the transducer or readings seem off.

Use a simulator or pressure calibrator (if available).

Apply known pressure (e.g., 1000 psi).

Adjust span on the display/controller to match applied value.

✅ If span is off and can’t be adjusted, sensor may be faulty.

STEP 3: VERIFY UNDER LOAD

Start material flow.

Monitor pressure readings under typical extrusion load.

Compare with expected range – if it looks wrong:

Double-check zero

Compare to backup gauge (if installed)

TROUBLESHOOTING – FAST FIXES

Symptom | Possible Cause | Quick Fix |

Stuck at max or min value | Broken sensor or wiring issue | Swap with known good sensor |

Won’t zero | Pressure still in system / damage | Vent barrel / replace sensor |

Fluctuating signal | Ground loop / EMI / loose wires | Check shield, reroute cables |

Reads zero under pressure | Span off or wrong range sensor | Check calibration / specs |

TIPS TO KEEP MOVING

Keep a spare transducer on hand.

Use quick-disconnect cabling if possible.

Don’t calibrate until system is at temp and pressure-free.

Document calibration date & operator for traceability.

Always consult your process management team for FORMAL process steps / these tips are for consideration and to start the conversation!

Comments