PURCHASING | Unlocking Cost Savings: The Advantages of Team Pricing Checks with New Suppliers

- Bob

- Sep 10, 2025

- 2 min read

Some Costs of Not Checking Pricing

Cumulative Price Creep

Annual increases of just 3–5% compound quickly.

Over 5 years, a $500 melt pressure transducer could end up at $600–$650 without competitive pressure.

If you buy 20–30 units a year, that adds up to tens of thousands in hidden cost.

Lost Leverage in Negotiation

Suppliers often assume “set it and forget it” customers won’t benchmark prices.

Without competition, they may stop offering discounts, bundled services, or stocking programs.

Missed Innovation / Durability Gains

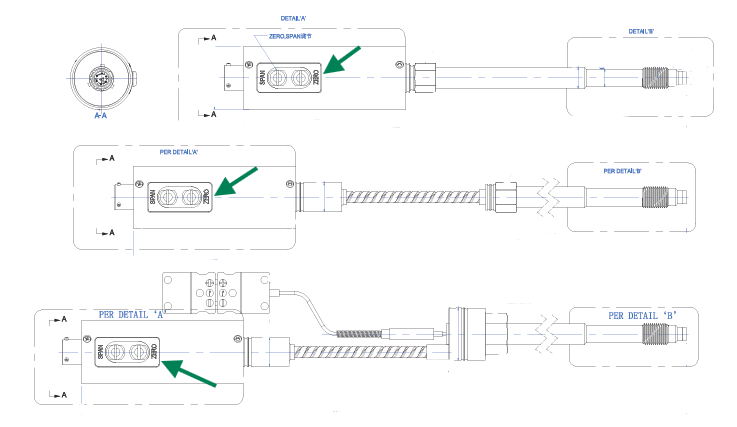

Not checking alternatives means the extrusion team may miss new sensor designs (e.g., longer-lasting diaphragms, dual-function models with integrated thermocouples).

That results in higher lifecycle costs (more frequent replacements, downtime).

Budget Impact Across Many Parts

It’s not just sensors — bearings, heaters, filters, thermocouples, etc.

Small unnoticed increases across dozens of MRO categories can equal a full salary or more in lost value annually.

Best Approach to Stay on Top of Offers & Value

Annual or Bi-Annual Benchmarking

Review critical spares and high-spend MRO parts against at least two alternative suppliers once or twice a year.

Use RFQs (Request for Quote) even if you don’t plan to switch immediately.

Dual Sourcing Strategy

Keep at least two approved suppliers for critical spares like melt pressure transducers.

Even if Supplier A has 80% of spend, Supplier B keeps pricing honest and provides backup.

Total Cost of Ownership (TCO) Reviews

Look beyond unit price:

Durability (lifespan, fewer failures).

Delivery (reduced downtime, faster lead times).

Service (calibration, technical support).

Sometimes a slightly higher purchase price = lower lifecycle cost.

Cross-Functional Supplier Reviews**

Involve engineering, maintenance, and operations in supplier scorecards.

This ensures purchasing isn’t just chasing the lowest price, but true value.

Market Scanning & Networking

Subscribe to supplier updates, industry newsletters, and distributor alerts.

Trade shows or technical webinars often showcase new offers before pricing shifts.

Summary for Purchasing Managers:

Not checking pricing leads to compounding hidden costs, decreased leverage, and missed innovation. The best safeguard is a structured approach:

Benchmark regularly.

Dual source critical parts.

Evaluate total cost of ownership.

Keep the extrusion team engaged in reviews**

Comments